Sterilization for medical equipment is vitally important since this process is used to render a product free from viable microorganisms. Steam is used in the many sterilization processes. The steam is put under pressure that is higher than the atmospheric pressure (> 1 bar).

DigiVac has been helping utility companies and companies that serve them for their vacuum needs. Vacuum is used for transformer maintenance including transformer degas, transformer oil purification, transformer dryout and transformer leak detection.

We find that Hastings vacuum gauge thermocouple tubes are often found permanently mounted in cryogenic vessels. Often, it’s ideal to have a battery operated vacuum gauge that enables you to walk along a cryogenic vessel, and measure the vacuum at that point. We have a variety of gauges that can measure vacuum with Hastings tubes.

The use of a digital vacuum gauge in HVAC and refrigeration maintenance can greatly increase the effectiveness of service calls and reduce the likelyhood of unpaid return visits to customers. There are often 5 phases of an HVAC call: Refrigerant Recovery, REFR system repair, Leak Check, Evacuation, and Charge.

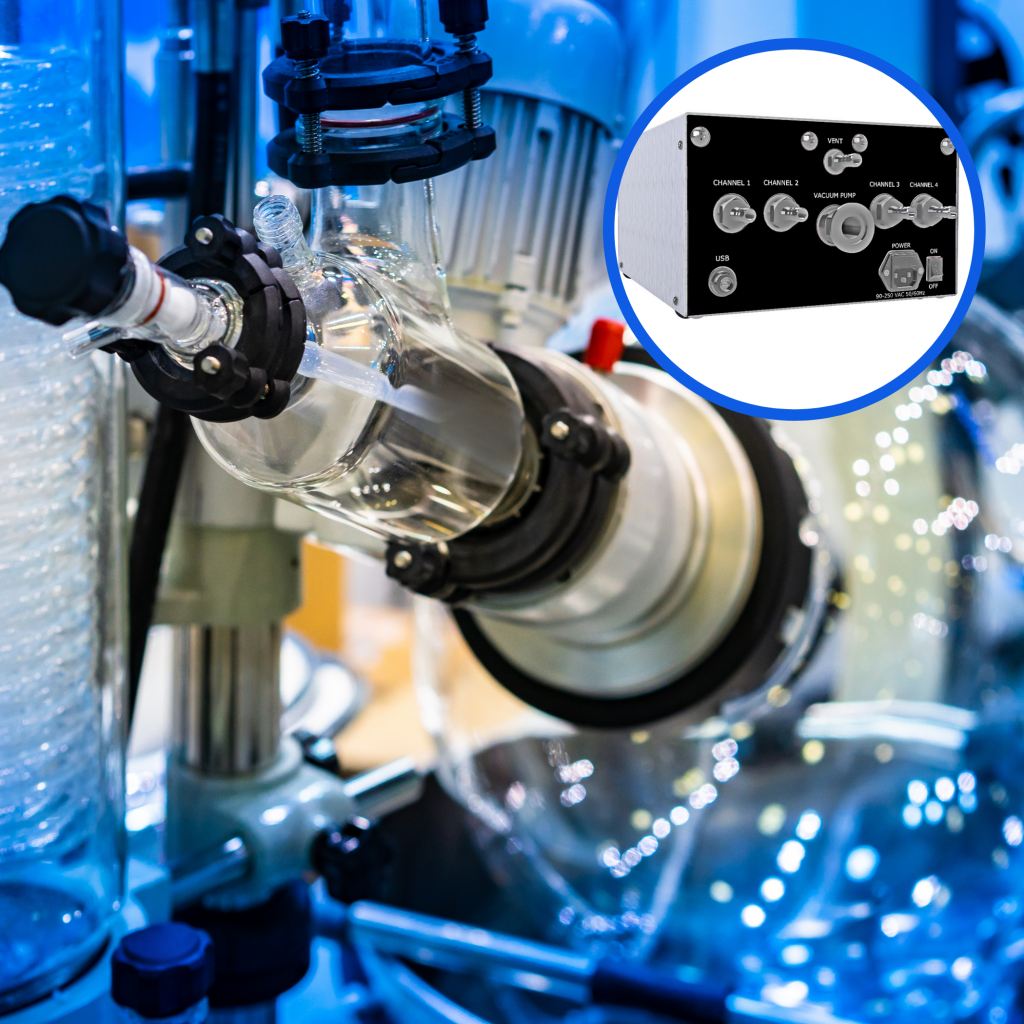

Short path distillation is a process that occurs after extraction. It is a type of botanical processing, generally utilized for the molecular separation of botanical fluids to achieve high potency. “Short path” refers to the short distance the oil travels, relative to the notoriously large industrial distillation units most people know. Wiped film distillation is a type of short path distillation.

Solvent recovery is a process that removes (or “recovers”) the solvent from a fluid after the extraction process. Solvent recovery is a type of post-processing, which can be performed with a rotary evaporator or thin film distillation unit. The solvent that is being removed is typically ethanol, CO2, or butane (i.e. whatever solvent that were used during the extraction process).